Invar alloy 36 /UNS K93600 & K93601

| U'amea fa'a'ofuofu | elemene | C | Si | Mn | S | P | Ni | Fe |

| Invar 36 | Min |

|

| 0.2 |

|

| 35.0 |

|

| Maualuga | 0.05 | 0.2 | 0.6 | 0.02 | 0.02 | 37.0 | paleni |

| Tulaga o Aolly | Fuainumera Laina Fa'atatau (10)-6/°C) | ||||

| 20~50℃ | 20~100℃ | 20~200℃ | 20~300℃ | 20~400℃ | |

| fa'a'aisa | 0.6 | 0.8 | 2.0 | 5.1 | 8.0 |

| Mafiafiakalama/senitimi3 | Tulaga e liusuavai ai℃ |

| 8.1 | 1430 |

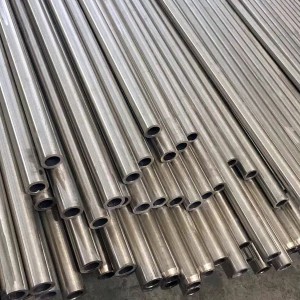

U'amea, Pa, Uaea ma le Fa'aputuga Fa'apala

Ipu, Pepa ma le Fa'asologa -ASTM B 388 ma le B 753

Tusi lau savali iinei ma lafo mai ia i matou